Global Variosystems Footprint

*Tap the bubbles to see Operation Hubs.

Europe

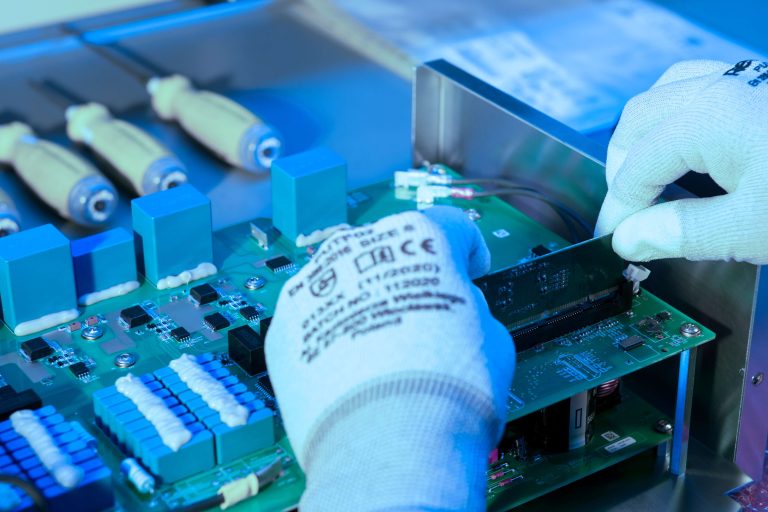

Headquartered in Steinach, Switzerland, Variosystems Europe supports customers in Switzerland, Germany, Austria and Italy. It offers electronics services along the entire value chain of electronics solutions from development, to industrialization, production and life-cycle management.

In Europe, Variosystems focuses on the medtech & life-science, aerospace & defense, smart infrastructure & environment as well as on the industrial & automation markets. The local customer success teams meet the complex requirements of these market sectors, ensuring compliance and precision in every project.

The VARIOincubator in Zizers plays a crucial role in the development and life-cycle management of electronics solutions. It enables the rapid transformation of product ideas into initial prototypes and their optimal preparation for series production in close collaboration with engineering teams.

In addition to the VARIOplatform operations hub in Switzerland, which focuses on regulated markets, the VARIOplatform in Croatia specializes on Box Build Assembly services. Many European customers appreciate the opportunity to have access to other VARIOplatforms, like the site in Sri Lanka with nearly 30’000 m² (323,000 ft²) of production space for first-class electronics solutions.

This comprehensive supply chain network in Europe, combined with our unwavering focus on customer satisfaction and operational excellence, positions Variosystems as a leader in delivering exceptional electronics solutions across Europe and beyond.

Operations Hubs

Zizers, Switzerland

Less than an hour’s drive from our headquarters, the VARIOincubator hub in Zizers is where we work with you to create tomorrow’s innovations, true to our purpose: co-creating leading innovators.

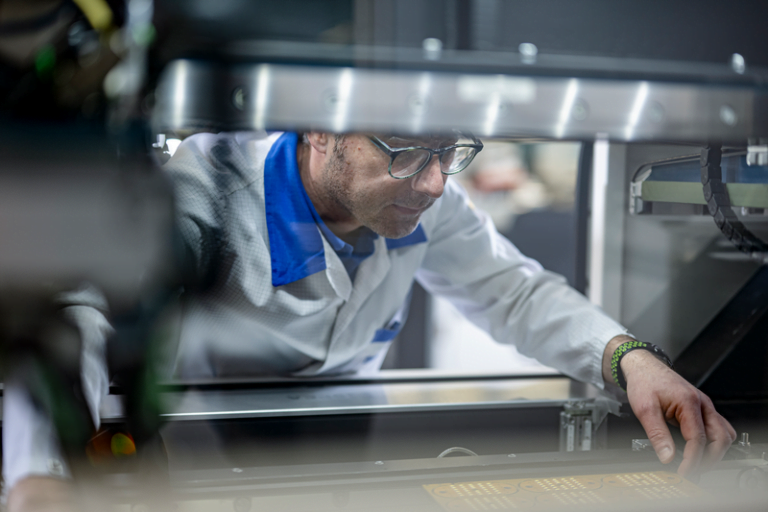

Specialized in rapid prototyping, our local experts bundle all services from the initial idea and development to industrialization and production of innovative electronics solutions. This enables us to significantly reduce the time-to-market for your products.

Steinach, Switzerland

The operations hub in Steinach, Switzerland, close to St. Gallen and Zurich, is strategically positioned to efficiently serve customers across Europe. It focuses on manufacturing services for the medtech & life-science and aerospace & defense industries, offering expertise in Printed Circuit Board Assembly and Box Build Assembly.

The Steinach hub, evolving from its modest beginnings to now covering over 8’500 m² (91,500 ft²), demonstrates our commitment to sustainable growth and operational excellence. The nearby VARIOincubator in Zizers further symbolizes our dedication to developing future technologies. This combination of strategic location, specialized competence and advanced manufacturing capabilities makes the Steinach operations hub a top choice for companies seeking excellence in electronics manufacturing.

The VARIOplatform hub in Steinach is ISO 9001, ISO 13485, ISO 14001, ISO 45001 and AS 9001 certified.

Ludbreg, Croatia

The operations hub in Ludbreg, Croatia, was founded in 2019 and serves as a Box Build Competence Center. Croatia is renowned for high quality and start-ups in various fields and industries and offers a strong network of mechanical suppliers. Paired with the customary Variosystems quality, this is a winning combination for components, wire harnesses and electronics solutions assembled in Ludbreg.

At this 1’200 m² (13,000 ft²) hub, specialist work takes place on mechanical assemblies, functional testing and machine engineering, with a particular focus on box build and hot/cold stamping. The quality of Variosystems Croatia is attested by ISO 9001 certification. To meet growing demand, we are expanding our capabilities and investing in a new hub.

Mendrisio, Switzerland

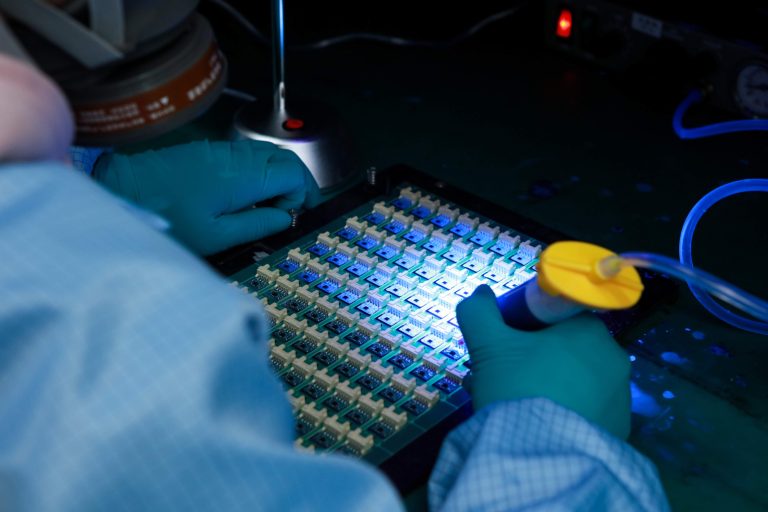

Equipped with state-of-the-art SMD and THT machines and specializing in conformal coating processes, targeted layouting and elaborate test procedures, our 7,500 m² (80,700 ft²) VARIOincubator Hub in Mendrisio provides the ideal conditions for the development of customized prototypes. Our team of 100 highly qualified staff will support you at every step along the way, from project management through component development and co-engineering to design for manufacturing and final testing.

By virtue of its strategic location, the VARIOincubator Hub in Mendrisio is able to serve the key Italian industrial centers of Milan (60 minutes away), Turin (at one and a half hours distance) and Veneto region (at 2.5 hours distance). But customers from western Switzerland and France are equally able to benefit from the expertise of our employees at the VARIOincubator in Mendrisio.

Gruiu, Romania

The Operations Hub in Gruiu specializes in the high-volume assembly of PCBs and modules. The production capacities include three SMD lines and THT assembly. This allows our European customers to benefit from local supply chains and at the same time from cost-efficient, large-scale electronics production.

On a floor area of 6,200 m² (66,700 ft²), our 200-strong workforce manufactures high-quality electronic solutions for our customers, including products for electromagnetic compatibility (EMC) such as chokes, transformers and block filters. To ensure consistently high quality, our Operations Hub team of experts use wave and selective soldering, apply protective coatings and submit everything to a comprehensive testing procedure.

Badalgama, Sri Lanka

Serving the needs of the European and Asia Pacific markets, the operations hub in Badalgama, Sri Lanka, is a vital facility of Variosystems, spanning 30,000 m² (323,000 ft²) and employing over 1,200 staff. This hub is the largest within the Variosystems group and offers a wide range of services from development and industrialization to production and life-cycle management. Sourcing, purchasing, logistics, test engineering, and quality management departments are housed within the same facility as well.

Equipped with six SMT lines and eight THT lines, this hub specializes in low-pressure molding processes for encapsulation and protection of electrical and electronic components. Over 400 employees are dedicated to wire harness assembly, indicative of our commitment to this crucial manufacturing process.

Additionally, the site boasts on-site test adapter manufacturing facilities, which enable rapid and high-quality testing. This comprehensive setup empowers the hub to efficiently meet diverse manufacturing requirements, especially in high-volume production. To underline Variosystems’ commitment to the highest quality standards, the Badalgama operations hub is certified according to ISO 9001, ISO 13485, ISO 45001, and ISO 14001, and includes UL-certified product manufacturing.

On top of offering best-in-class electronics manufacturing services in Sri Lanka, Variosystems is committed to the local community’s development. The company hosts on-campus training centers and agricultural activities, invests in local schools, and operates an extensive renewable energy system in the region.

North America

Variosystems North American is headquartered in Southlake, USA and supports customers in the United States and Canada. It offers electronics services along the entire value chain of electronics solutions from development, to industrialization, production and life-cycle management.

In North America, Variosystems focuses on medtech & life-science, industrial & automation, smart infrastructure & environment as well as high-end consumers.

In the North America region, Variosystems offers two VARIOplatform operations hubs in the US, one in Southlake, Texas being focused on PCBA manufacturing services and one in Fort Worth, that offers Box Build Assembly services. The third VARIOplatform in the region is located in Juarez, Mexico, offering manufacturing services in Printed Circuit Board Assembly, Box Build Assembly and Wire Harness Assembly.

Variosystems North America supports its customers in their nearshoring activities to develop and implement electronics supply chains in the other regions of the world, like Europe, China and Asia Pacific.

This comprehensive supply chain network in North America, combined with our unwavering focus on customer satisfaction and operational excellence, positions Variosystems as a leader in delivering exceptional electronic solutions across North America and beyond.

Operations Hubs

Southlake, USA

In 1999, Variosystems opened its first hub in the advantageously central location of Southlake, Texas. A highly skilled workforce is based here in state-of-the-art facilities measuring 6’000 m² (65,000 ft²). At this operations hub, the production has steadily expanded to now offer complete solutions, from development, to industrialization, production and life-cycle management. Current specialties include SMT and THT assembly, wave and selective wave soldering, potting and conformal coating.

With more than 300 employees in the Dallas-Fort Worth Metroplex, Variosystems is one of the leading electronics employers in the south-central United States. This combination of expertise and operational excellence enables our local team to continuously produce first-class electronics solutions for our customers.

The VARIOplatform hub in Southlake is ISO 9001, ISO 13485 and IATF 16949 certified.

Fort Worth, USA

To meet the increasing demand for nearshored integrated electronics solutions, Variosystems opened its second Texas hub in Fort Worth in 2020, serving as the center of excellence for electro-mechanical assembly processes such as overmolding, box build assembly and system integration.

The additional capabilities in Fort Worth enable us to turn customer requirements into real products even faster.

Juárez, Mexico

Located in Juárez, just across the border, the operations hub Mexico is conveniently located a short distance from the US hubs in Texas. With two airports also within a short distance, this site is well-placed to serve the growing demand for electronics in North America.

Our Juárez hub is a high-volume production site with three SMT lines and three THT lines across 6’500 m² / 70,000 ft². Due to the global harmonization of Variosystems’ processes, the site has identical production equipment and standardized processes, software and hardware. This ensures that customers can expect the same high quality worldwide, regardless of production location. This makes Juárez a perfect fit for the Customer Organization North America and an ideal nearshoring partner for high-volume Printed Circuit Boards, Wire Harness or Box Build Assembly.

China

Headquartered in Suzhou, Variosystems China excels in providing a full spectrum of electronics services, from development and industrialization to production and life-cycle management, catering to industries like mobility & transportation, industrial & automation, medtech & life science as well as high-end consumers.

In China, Variosystems leverages its industry-focused customer success teams to meet the intricate demands of these markets, ensuring projects are executed efficiently from concept to completion. The teams specialize in reducing the complexity of rapid prototyping through to high-volume production, ensuring precision and compliance on every project.

The strategic utilization of local supply chains by Variosystems China significantly enhances operational efficiency and reduces time-to-market, providing a competitive advantage in the fast-paced Chinese market. This approach ensures that services and products are closely aligned with the unique needs and standards of local industries, providing customers with high quality, timely solutions.

Variosystems China’s commitment to excellence in electronics solutions, combined with its deep understanding of the local market, positions itself as a leader in delivering high quality electronics solutions within China, enabling customers with the agility and quality they need to succeed in their respective fields.

Operations Hubs

Suzhou, China

Our VARIOincubator Hub in Suzhou, China, specialises in PCB layout and rapid prototyping. Our onsite team of experts turns your ideas into reality quickly while complying with the highest quality standards. The combination of expertise and technology enables us to respond precisely to your requirements and develop customised solutions efficiently.

You also benefit from the direct connection to the local VARIOplatform hub. This enables us to ensure a smooth transition from product development to series production, significantly accelerating your time-to-market.

Suzhou, China

Housed in the technology center of Suzhou, the VARIOplatform in China spans over 10,700 m² (115,000 ft²) and is staffed by over 350 highly skilled employees. While the operations hub serves as a manufacturing powerhouse supporting rapid prototyping and high-volume production, Suzhou also serves as the sales center for the Chinese market.

Specializing in the areas of mobility & transportation and industrial & automation, this facility integrates advanced manufacturing with customer-focused solutions, featuring six SMT and four THT lines. The commitment to innovation and operational excellence is evident in the use of cutting-edge technologies for component protection and machine engineering.

The focus on mobility & transportation is demonstrated through tailored solutions for off-road vehicles and marine devices. Additionally, expertise in industrial controllers, sensors and actuators meet the high standards of the modern industrial & automation industry.

The Suzhou operations hub has been certified according to ISO 9001, ISO 45001, ISO 14001, and IATF 16949. This exemplified Variosystems commitment to quality in order to serve a diverse range of products for various industries.

Asia Pacific

Variosystems Asia Pacific, headquartered in Singapore, brings products and services closer to multinational customers throughout the Asia Pacific region, including Australia. The customer success team, based in Singapore and Sri Lanka, delivers best-in-class electronics solutions to customers operating within Asia Pacific, covering everything from development and industrialization to production and life-cycle management.

Specializing in sectors such as industrial & automation, mobility & transport, medtech & life-science, aerospace, smart infrastructure, and high-end consumers, reflects the diverse global customer base of Variosystems.

The uniqueness of Variosystems Asia Pacific stems from combining local expertise with the extensive resources of the VARIOplatform operations hubs in Badalgama, Sri Lanka, and Suzhou, China. Embracing a ‘care locally, operate globally’ ethos, Variosystems Asia Pacific ensures exceptional service and support, aiming for success in the dynamic Asia Pacific market.

Operations Hub

Badalgama, Sri Lanka

Serving the needs of the European and Asia Pacific markets, the operations hub in Badalgama, Sri Lanka, is a vital facility of Variosystems, spanning 30,000 m² (323,000 ft²) and employing over 1,200 staff. This hub is the largest within the Variosystems group and offers a wide range of services from development and industrialization to production and life-cycle management. Sourcing, purchasing, logistics, test engineering, and quality management departments are housed within the same facility as well.

Equipped with six SMT lines and eight THT lines, this hub specializes in low-pressure molding processes for encapsulation and protection of electrical and electronic components. Over 400 employees are dedicated to wire harness assembly, indicative of our commitment to this crucial manufacturing process to meet your expectations.

Additionally, the site boasts on-site test adapter manufacturing facilities, which enable rapid and high-quality testing. This comprehensive setup empowers the hub to efficiently meet diverse manufacturing requirements, especially in high-volume production. To underline Variosystems’ commitment to the highest quality standards, the Badalgama operations hub is certified according to ISO 9001, ISO 13485, ISO 45001, and ISO 14001, and includes UL-certified product manufacturing.

On top of offering best-in-class electronics manufacturing services in Sri Lanka, Variosystems is committed to the local community’s development. The company hosts on-campus training centers and agricultural activities, invests in local schools, and operates an extensive renewable energy system in the region.

Facilities worldwide

Million Swiss francs in annual sales

Employees worldwide

NEWSLETTER

You want to stay informed about latest market developments, trends and news about Variosystems? Then register here.

DoMedia

DoMedia